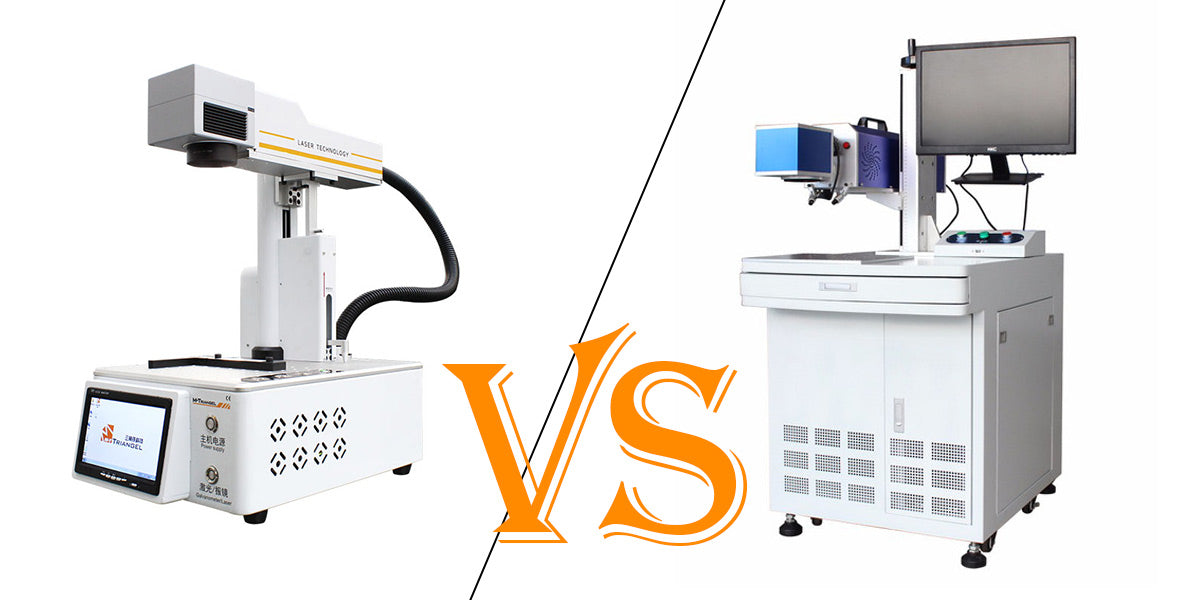

Laser marking machine is also called laser coding machine, they are both used for marking and engraving, but do you understand the difference between fiber laser marking machine and UV marking machine?

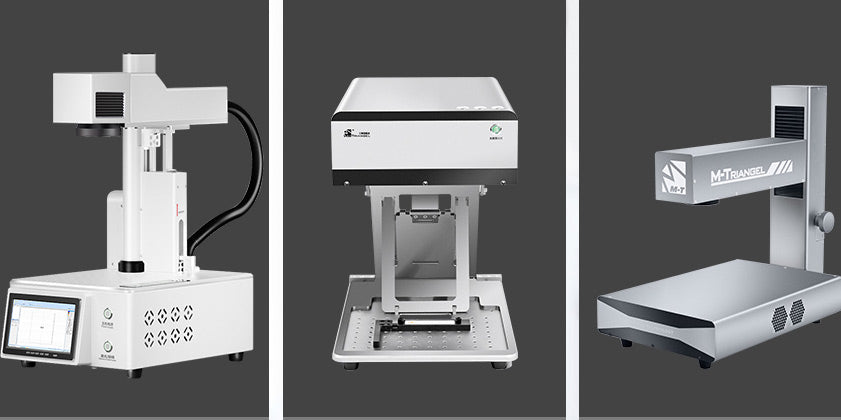

Fiber laser marking machine performance and features

- Marking software is powerful, compatible with CorelDRAW, AutoCAD, illustrator and other software files; support PLT, PCX, DXF, BMP, etc., can directly use SHX, TTF font; support automatic coding, printing serial number, batch number, date, bar code, two-dimensional code, automatic jump number, etc.

- Use integrated overall structure, equipped with automatic focus system, humanized operation process.

- Using isolator to protect the fiber laser window, enhance the stability and laser life.

- Without any maintenance, long service life, small size, suitable for a variety of environmental work.

- Fast processing speed, 2-3 times faster than traditional marking machine.

- High efficiency of electro-optical conversion, small power consumption of the machine, greatly saving energy expenditure.

- Beam quality is much better than the traditional solid-state laser marking machine, dispersion angle is 1/4 of the semiconductor pump laser, particularly suitable for fine, precision marking.

UV laser marking machine

The concentrated light is tiny, there is no thermal impact, no impact on the surrounding, suitable for more delicate processing, suitable for many non-metallic materials processing.

And one is cold processing, one is hot processing, UV laser marking is cold processing, fiber laser is hot processing. UV and fiber are lasers, but the wave length is different, so the name is different.

UV laser processing process called "photo-etching" effect, "cold processing" has a very high load energy (UV) photons, to break the material (especially organic materials) or the surrounding media within the chemical bond, to make the material to non-thermal process damage. No heating or thermal deformation or other effects on the lining of the processed surface and nearby areas, suitable for fine processing. Fiber laser marking machine is through the laser beam to evaporate the surface material to reveal the deep material, or through the light energy to cause chemical and physical changes in the surface material and "engraved" traces, or through the light energy to burn off part of the material, showing the required etching patterns, text, bar codes and other types of graphics, suitable for metal products processing.